Laboratory of Production Systems

Production Systems Laboratory conducts several practicum sessions, namely: Engineering Drawing Practicum, CAD Practicum, Control Theory and Introduction to Automation Practicum, Robotics & FMS Practicum, Production Planning & Inventory Control Practicum, and Facility Layout Design Practicum.

A. Engineering Drawing Practicum

The Engineering Drawing Practicum supports the Engineering Drawing course (IMG244). The practicum covers how to draw products according to technical drawing standards in both 2D and 3D formats.

B. CAD Practicum

The CAD Practicum is part of the Manufacturing Industry Design II Practicum (IIP222). It involves designing a product in 2D and 3D using AutoCAD software, as well as developing detailed product designs based on students’ creativity to maximize the use of AutoCAD commands.

C. Control Theory and Introduction to Automation Practicum

This practicum is also part of the Manufacturing Industry Design II Practicum (IIP222). It includes identifying and understanding actuators and controllers to design automation systems in manufacturing industries. The topics are further elaborated in the elective course “Automated Manufacturing Systems” (IIP334).

D. Robotics & FMS Practicum

The Robotics & FMS Practicum is part of the Manufacturing Industry Design II Practicum (IIP222). It includes planning and programming operations using Fisher Technik robots, as well as developing programming languages to operate machines automatically (part programming).

E. Production Planning & Inventory Control Practicum

The PPIC Practicum is part of the Production Planning and Control I and II courses. It covers forecasting product demand for future periods, determining production resource requirements, performing aggregate production planning, disaggregating to develop a master production schedule, verifying the master schedule using Rough Cut Capacity Planning, creating material requirements planning, checking plan order releases with Capacity Requirement Planning, scheduling machines to fulfill product orders, and designing assembly line balancing.

F. Facility Layout Design Practicum

The Facility Layout Design Practicum is part of the Manufacturing Industry Design III Practicum (IIP132). It involves designing a factory layout both manually and using software, covering the following components:

- Assembly Chart, Standard Time, Operation Process Chart (OPC), Routing Sheet

- MPPC, Machine Requirement Calculation, Production & Warehouse Floor Area

- Production MHPS, GKP, GBP, FTC Cost, FTC Inflow/Outflow, Material Handling Area

- Priority Scale, Production ARD

- Organizational Structure, Job Descriptions, Office & Plant Service Area

- Production & Warehouse AAD, Factory ARC

- Factory Priority Scale & Factory ARD

- Factory AAD, Office Layout, MHES

- Templates & Presentations

G. Manufacturing Process Practicum

The Manufacturing Process Practicum is part of the Manufacturing Process and Practicum course (IIP321). In addition to practicum activities, the laboratory also organizes research and training activities:

1. Research:

Research is conducted by Industrial Engineering students as part of their final projects. Additionally, faculty members carry out research, the results of which are published in seminar proceedings, symposium proceedings, and industrial engineering journals.

2. Training:

The training programs held include:

- AutoCAD Training

- AIMMS Training

- Production Planning and Control Training

- MATLAB Application Training

3. Collaboration:

The laboratory collaborates with FESTO for the use of laboratory equipment, inventory management training with PT. Kayaba Indonesia, community service programs with PT. Bekaert and Jababeka management.

Collaboration is also carried out with PT Komatsu Indonesia for research involving both faculty and students. Furthermore, the Production Systems Laboratory has conducted several community service programs at PT Komatsu Indonesia.

4. Seminar:

National Seminar on Facilities Planning

5. Competition:

Facilities Planning Competition

6. Workshop:

Facilities Planning Workshop

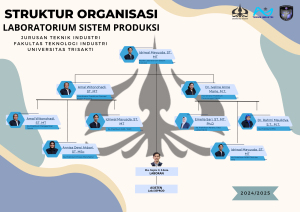

| Head of the Production Systems Laboratory | : | Idriwal Mayusda, ST. MT |

| Coordinator of the Production System Automation Practicum | : | Amal Witonohadi, ST, MT |

| Head of CAD / CAM Practicum | : | Idriwal Mayusda, ST. MT |

| Coordinator of the Production System Automation Practicum | : | Amal Witonohadi, ST, MT |

| Head of Engineering Drawing Practicum | : | Amal Witonohadi, ST, MT |

| Head of Manufacturing Process Practicum | : | Annisa Dewi Akbari, ST, M.Sc |

| Coordinator of the Factory Design Practicum | : | Dr. Iveline Anne Marie, M.T. |

| Head of Factory Layout Design Practicum | : | Emelia Sari, ST, MT, Ph.D |

| Head of PPIC Practicum | : | Dr. Rahmi Maulidya, S.T., M.T. |

| Head of Robotics and FMS Practicum | : | Idriwal Mayusda, ST. MT |

| Laboratory | : | Eko Noptu N, S.Kom. |

| Laboratory Member | : | Prof. Dadan Umar Daihani, DEA Prof. Parwadi Moengin, PhD Dr. Tiena G. Amran, MSc Ir. Didien Suhardini, Ph.D Ir. Sumiharni Batubara, MSc. Dr. Ir. Nora Azmi, MT. Dian Mardi Safitri, ST, MT Agung Sasongko, ST, MM Novia Rahmawati, ST, MT, MBA |

Sekretariat :

Gd. F&G Lt. 2 & 5, Kampus A USAKTI