The Production Systems Laboratory organizes practicums, namely: Technical Drawing Practicum, CAD Practicum, Control Theory Practicum and Introduction to Automation, Robotics & FMS Practicum, Production Planning & Inventory Control Practicum, Factory Layout Design Practicum.

A. Technical Drawing Practicum Technical Drawing Practicum is a practicum that supports the Engineering Drawing course (IMG244), with practical material on how to draw products according to the rules of technical drawing in 2-dimensional and 3-dimensional forms.

B. CAD Practicum The CAD practicum is part of the Manufacturing Industry Design Practicum II (IIP222), with practical material on drawing a product design in 2-dimensional and 3-dimensional form using AutoCad software and developing detailed product designs based on the creativity of the practitioner to maximize the use of commands in Auto Cad.

C. Control Theory Practicum & Introduction to Automation The Control Theory & Introduction to Automation Practicum is part of the Manufacturing Industry Design Practicum II (IIP222), with practical material on recognizing and understanding actuators and controllers to design automation systems in the manufacturing industry. This material will be given further in the Automated Manufacturing System Optional Course (IIP334).

D. ROBOTICS & FMS Practicum The ROBOTICS & FMS Practicum is part of the Manufacturing Industry Design Practicum II (IIP222), with practical material on making work plans and programs for an operation using a Fisher Engineering robot, as well as developing a programming language to run machines automatically (part programming).

E. Production Planning & Inventory Control Practicum PPIC practicum is part of the Production Planning and Control course I and II, with practicum material for forecasting product demand for several periods to come, determining production resource requirements, making aggregate production plans, conducting a disaggregation process to obtain a master production schedule, carrying out checking the master production schedule using Rough Cut Capacity Planning, making material requirements planning, checking the order release plan using Capacity Requirement Planning, scheduling machines to make ordered products, designing assembly line balances.

F. Facility Layout Design Practicum The Facility Layout Design Practicum is part of the Manufacturing Industry Design Practicum III (IIP132), with practicum material for designing the layout of a factory both manually and computerized consisting of:

- Assembly chart, Standard Time, OPC, Routing Sheet

- MPPC, Number of Machinery Requirements, Production Floor Area & Warehouse

- MHPS Production, GKP, GBP, FTC Cost, FTC Inflow/Outflow, Material Handling Area

- Priority Scale, ARD Production

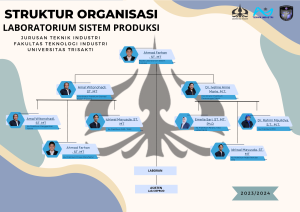

- Organizational Structure, Job Description, Office Area & Service Plant

- AAD Production & Warehousing, ARC Manufacturing

- Factory Priority Scale & Factory ARD

- AAD Factory, Office Plan, MHES

- Templates & Presentations

G. Manufacturing Process Practicum Manufacturing Process Practicum is part of the Manufacturing Process and Practical (IIP321) course. Apart from practicum activities, research and training activities are also held: 1. Study : The research was carried out by students of the Industrial Engineering Study Program for the Final Project, besides that research was carried out by lecturers whose results were published in Proceeding Seminars, Proceedings of Symposiums and Industrial Engineering Journals.

2. Training: